Products By market

Cosmetics

Use Cases

Cosmetics Manufacturer

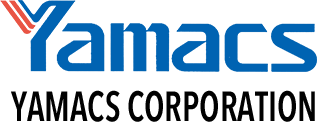

| Used for: | Compact case |

|---|---|

| Product used: | Panel |

| Print method: | Silkscreen printing |

Problem

Where an intricate design is required or when a mold or plating is needed for one-off cosmetic products, etc., it is not effective to do in small quantities. There is a limit to what can be down with the design when printing directly on containers or when hot stamping.

Yamacs’ Proposal

Yamacs recommended a very designable UV film print.

Solution

We first proposed inserting a UV printing film into the compact case whose lid is shaped into two parts, and then evaluated its appearance.

Result

As the compact case could be used for other product purposes the UV printing meant the case could be used again, something which wasn’t possible with the conventional direct print / hot stamping designs. This helped avoid overstocking of the cases.

The design was also highly regarded meaning it could be used for limited-edition / small run products.

Customer Feedback

I was very happy with the quality for our limited-edition cosmetics and small run products. (Designer)

Cosmetics Manufacturer

| Used for: | Compact Case |

|---|---|

| Product used: | Panels |

| Print method: | Inkjet printing |

Problem

The manufacturer wants to use a decorative sheet for a cosmetics case as one its planned products. If using silkscreen printing the many different types and colors stretches the budget too much, and it is also difficult to reproduce the intricate pattern of the design.

Yamacs’ Proposal

Yamacs recommended inkjet printing for the decorative design.

Solution

Various designs were trialled to see how well the designs and patterns could be reproduced.

Result

There were no problems reproducing the patterns in the trials. With inkjet printing a printing plate is no longer needed so it was possible to reproduce the intricate designs, something which was difficult with other print methods.

Customer Feedback

Using inkjet printing we were able to recreate the traditional Japanese pattern with its many different colors. (Designer)

Cosmetics Manufacturer

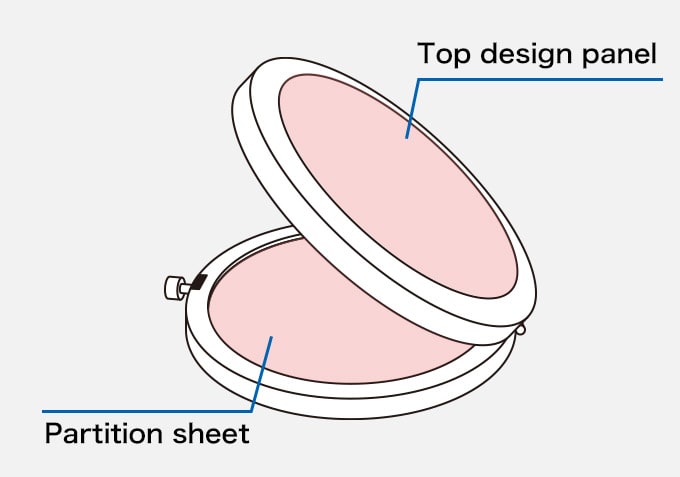

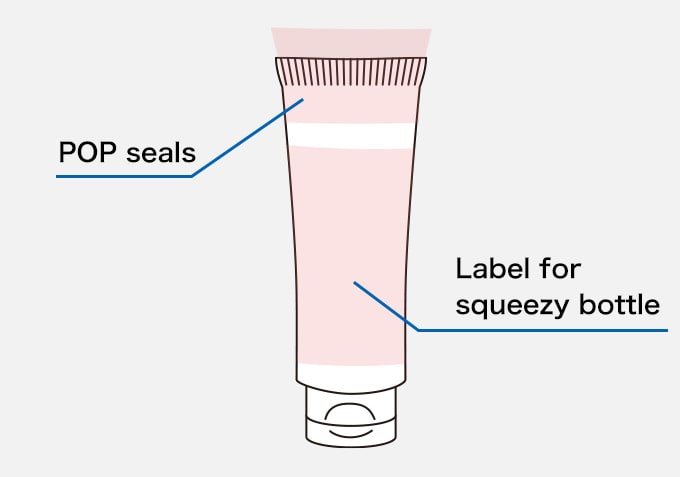

| Used for: | Tube |

|---|---|

| Product used: | Bottle label |

| Print method: | Offset / relief printing |

Problem

When printing directly on to tubes there’s a limit to how well photographs and intricate designs can be reproduced meaning that the scope of design is also limited with direct printing.

Yamacs’ Proposal

Yamacs recommended the use of squeeze tube labels with offset printing.

Solution

We did an offset print on polyolefin-type materials and created a prototype with a glossy print finish. We then checked for peeling and ink adhesion, etc. from physical property evaluations on the workability of sticking the labels, the squeezability (crease-flex abrasion test), and chemical resistance.

Result

There was no creasing or peeling even when attached to the tube. We could use photographs, etc., in the design enabling the commercialization of designs not possible before.

Customer Feedback

Many more designs were possible. I’ll definitely ask again for this kind of design which can only be done with labels. (Designer)